Description

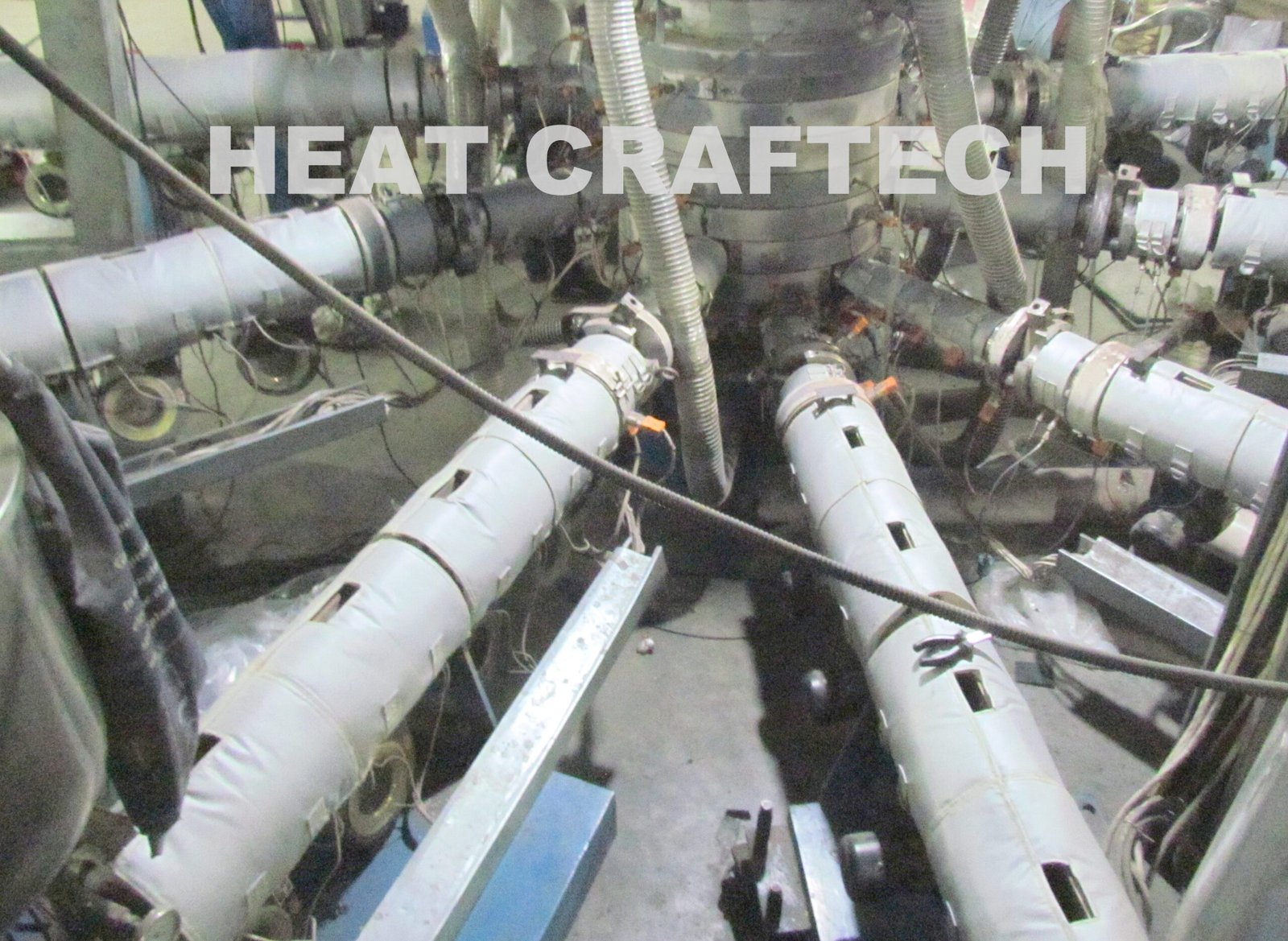

Heat Craftech: Optimizing Performance with 5-Layer Polyethylene Extruders

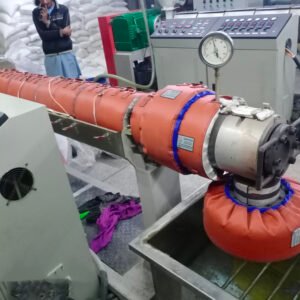

At Heat Craftech, we understand the growing demand for high-performance plastic films in various industries. 5-layer polyethylene extruders represent a cutting-edge technology for producing these advanced films with specific functionalities. We can help you optimize your 5-layer polyethylene extrusion process for superior product quality and production efficiency.

What is a 5-Layer Polyethylene Extruder?

A 5-layer polyethylene extruder is a specialized machine designed to create plastic films with distinct properties in each layer. This allows for the creation of films with targeted characteristics, such as:

- Enhanced Barrier Properties: Certain layers can be formulated to block specific gases, moisture, or light, ideal for food packaging or medical applications.

- Improved Mechanical Strength: Specific layers can be chosen to increase puncture resistance, tear strength, or overall film durability.

- Surface Aesthetics: Outer layers can be formulated for printability, gloss finish, or other desired visual characteristics.

How Does a 5-Layer Polyethylene Extruder Work?

- Feeding System: Different types of polyethylene resins are fed into separate hoppers.

- Extrusion and Melting: Each feed screw independently melts and pressurizes its respective resin.

- Multi-Manifold System: A complex system of channels combines the molten polyethylene streams from each extruder into a layered flow.

- Die Head: The die head shapes the layered flow into a uniform film of the desired thickness.

- Haul-Off and Cooling: The film is pulled through a haul-off unit and cooled down to solidify the final structure.

- Winding: The finished film is wound onto a roll for further processing or storage.

Benefits of Using a 5-Layer Polyethylene Extruder:

- Production of High-Performance Films: Create films with tailored properties to meet specific application requirements.

- Reduced Material Waste: By incorporating different functionalities in distinct layers, the need for multiple film types can be minimized.

- Enhanced Efficiency: 5-layer films can sometimes outperform single-layer films, leading to potential material savings and improved production efficiency.

Heat Craftech’s Role in 5-Layer Polyethylene Extrusion:

We offer a range of solutions to optimize your 5-layer extrusion process:

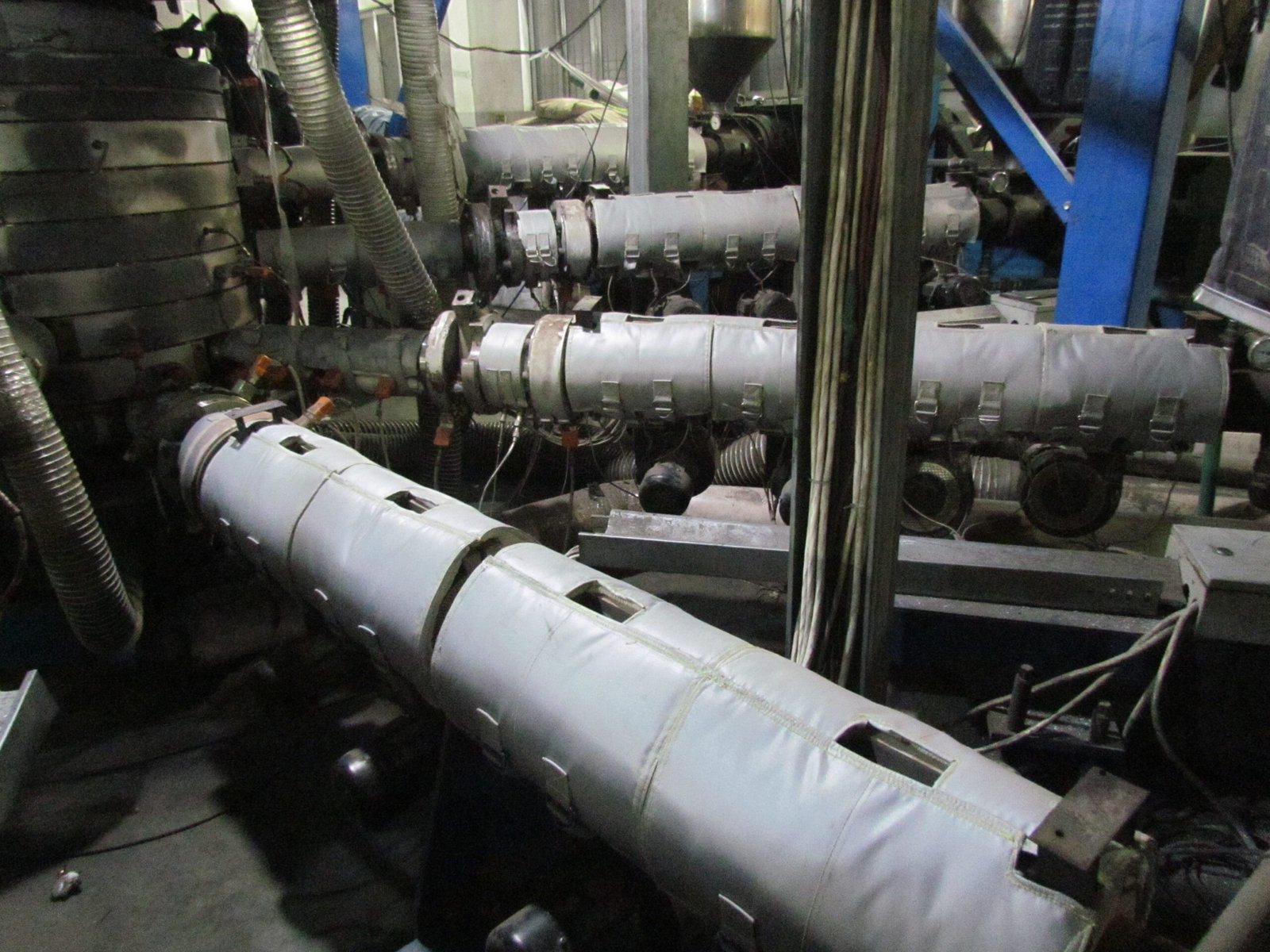

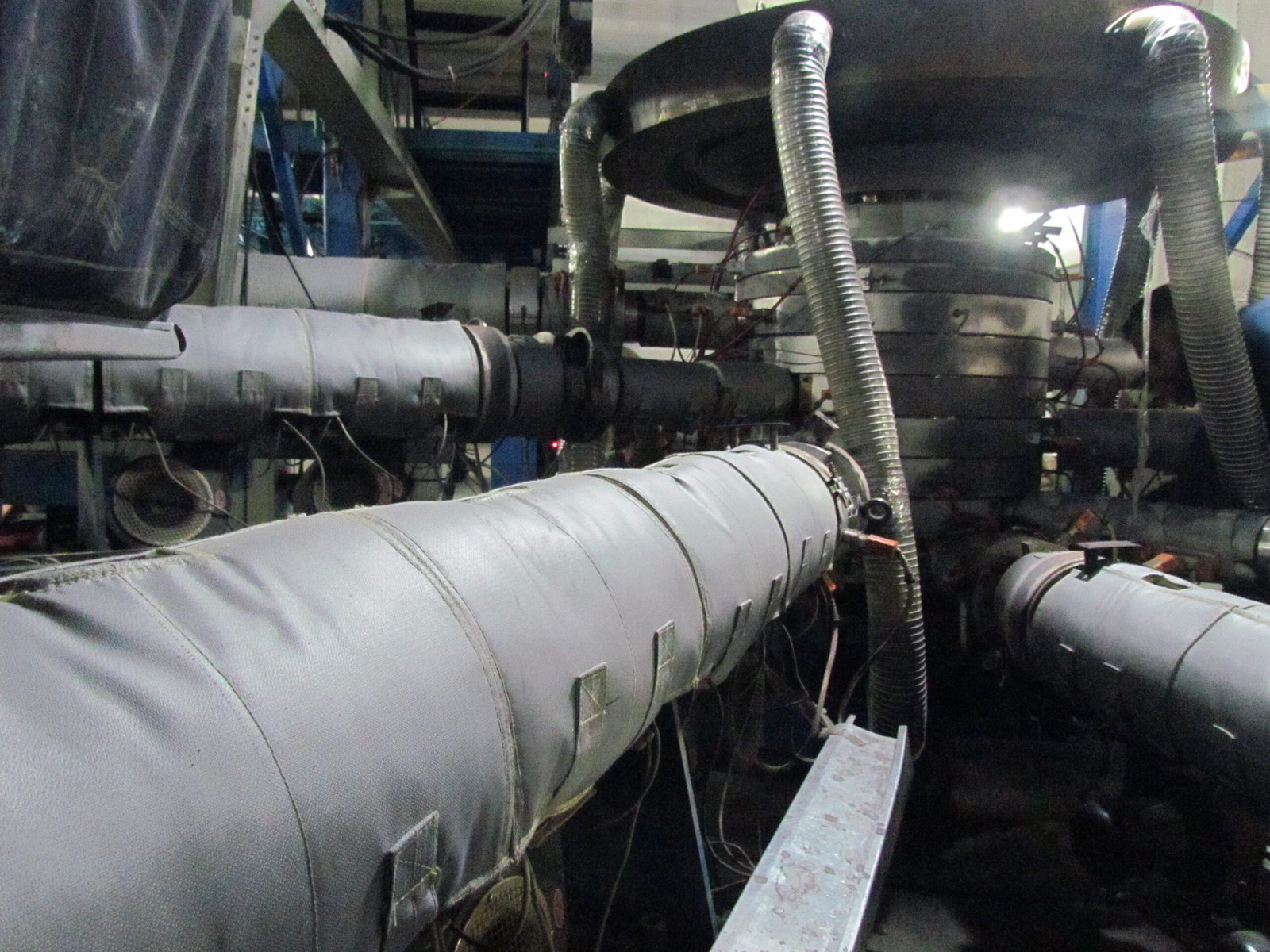

- Heat Insulation Jackets: Custom-designed jackets for each extruder ensure consistent melt temperatures for each layer, maintaining optimal material properties.

- Precise Temperature Control Systems: We provide advanced temperature control systems to manage the independent heating of each layer, ensuring consistent quality throughout the film.

- Technical Expertise: Our team of specialists can assist you with selecting the most suitable 5-layer extruder system, optimizing your process parameters, and troubleshooting any production challenges.

By partnering with Heat Craftech, you can achieve:

- Superior Film Quality: Precise temperature control and optimized layer configurations lead to films with consistent properties and minimal defects.

- Increased Production Efficiency: Reduced downtime, optimized material usage, and improved overall process efficiency.

- Enhanced Product Functionality: The ability to create films with targeted properties allows you to cater to specific market demands.

Contact Heat Craftech Today!

Let Heat Craftech be your trusted partner in 5-layer polyethylene extrusion. Contact us today to discuss your specific requirements and explore how our solutions and expertise can elevate your film production to the next level.

Reviews

There are no reviews yet.