Description

Heat Craftech: Understanding Polyester Fiber – A Versatile Material

At Heat Craftech, we’re dedicated to providing solutions across the plastics industry, and that includes the ever-present world of polyester fiber. This synthetic fiber, derived from petroleum or recycled materials, offers a wide range of desirable properties that make it a popular choice in textiles, industrial applications, and more.

What is Polyester Fiber?

Polyester fiber is a manufactured fiber created by polymerizing a substance called polyethylene terephthalate (PET). The process involves a chemical reaction that transforms PET into long, continuous strands. These strands can then be further processed into various forms, such as filaments, yarns, or staple fibers.

Key Properties of Polyester Fiber:

- High Strength and Durability: Polyester is known for its excellent strength and resistance to tearing and abrasion. This makes it ideal for applications requiring long-lasting performance.

- Wrinkle Resistance: Unlike natural fibers like cotton, polyester is naturally wrinkle-resistant and retains its shape well.

- Dimensional Stability: Polyester fibers maintain their size and shape effectively, minimizing shrinkage or stretching.

- Fast Drying: Polyester absorbs minimal moisture and dries quickly, making it a good choice for activewear or frequently washed textiles.

- Versatility: Polyester can be blended with other fibers like cotton to combine its desirable properties with the comfort of natural materials. It can also be dyed in a wide range of colors.

Applications of Polyester Fiber:

The versatility of polyester makes it a popular choice in numerous applications, including:

- Textiles: Polyester is a major component in clothing, sportswear, bedding, and other textile products.

- Industrial Fabrics: Its strength and durability make it suitable for conveyor belts, filtration materials, and industrial wipes.

- Home Furnishings: Polyester is often used in carpets, upholstery, and other home furnishing applications.

- Bottles and Containers: Recycled PET can be transformed into new bottles and containers, promoting sustainability.

- Composites: Polyester fibers can be combined with resins to create composite materials used in construction, automotive parts, and other applications.

Heat Craftech and Polyester Fiber:

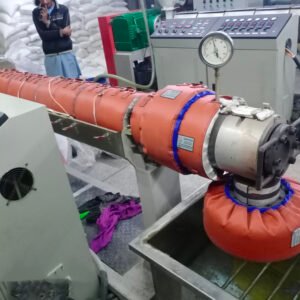

While Heat Craftech doesn’t directly manufacture polyester fiber, our expertise in heat management can be valuable in its production process:

- Temperature Control for Melt Spinning: The process of creating polyester fibers involves melting PET pellets. Precise temperature control during this stage is crucial for ensuring consistent fiber quality. We can provide solutions for heating and insulating equipment involved in melt spinning.

- Heat Setting for Fabrics: Heat setting is a process used to set wrinkles or pleats in polyester fabrics. We offer heat management solutions for industrial dryers and curing ovens used in this process.

Conclusion:

Polyester fiber is a versatile and widely used material with a range of desirable properties. At Heat Craftech, we understand the importance of this material and how proper heat management can contribute to its efficient production and use in various applications.

Reviews

There are no reviews yet.