Description

Heat Craftech: Understanding Mono Filament – The Versatile Single Strand

At Heat Craftech, we’re passionate about all things plastic, and that includes the fascinating world of mono filament. This seemingly simple product, a single strand of synthetic fiber, has a wide range of applications across various industries.

What is Mono Filament?

Mono filament, often shortened to “mono,” is essentially a single, continuous fiber extruded from melted plastic polymers like nylon, polyester, or polypropylene. Unlike yarns or threads, which are bundles of multiple fibers, mono filament offers a unique set of characteristics.

Key Properties of Mono Filament:

- High Strength: Mono filament can be surprisingly strong for its size, making it suitable for applications requiring tension or load bearing.

- Dimensional Stability: It maintains its shape well and resists stretching or breaking under moderate pressure.

- Lightweight: Mono filament is very light, making it ideal for applications where weight minimization is crucial.

- Chemical Resistance: Depending on the chosen polymer, mono filament can be resistant to various chemicals and weather conditions.

Applications of Mono Filament:

The versatility of mono filament allows it to be used in a surprising array of applications. Here are just a few examples:

- Fishing Line: Perhaps the most well-known use, mono filament fishing line is valued for its strength, invisibility in water, and affordability.

- Sutures: Medical-grade mono filament sutures are used for stitching wounds due to their biocompatibility and controlled breakdown properties.

- Bristles: Found in brushes for various applications, mono filament bristles offer durability and cleaning effectiveness.

- Fabrics: Woven or knitted mono filament can create lightweight, breathable fabrics for sportswear or industrial applications.

- Strings: Used in tennis rackets, musical instruments, and other applications requiring a strong, flexible string.

- 3D Printing: Some 3D printing processes utilize mono filament as the printing material.

Heat Craftech and Mono Filament:

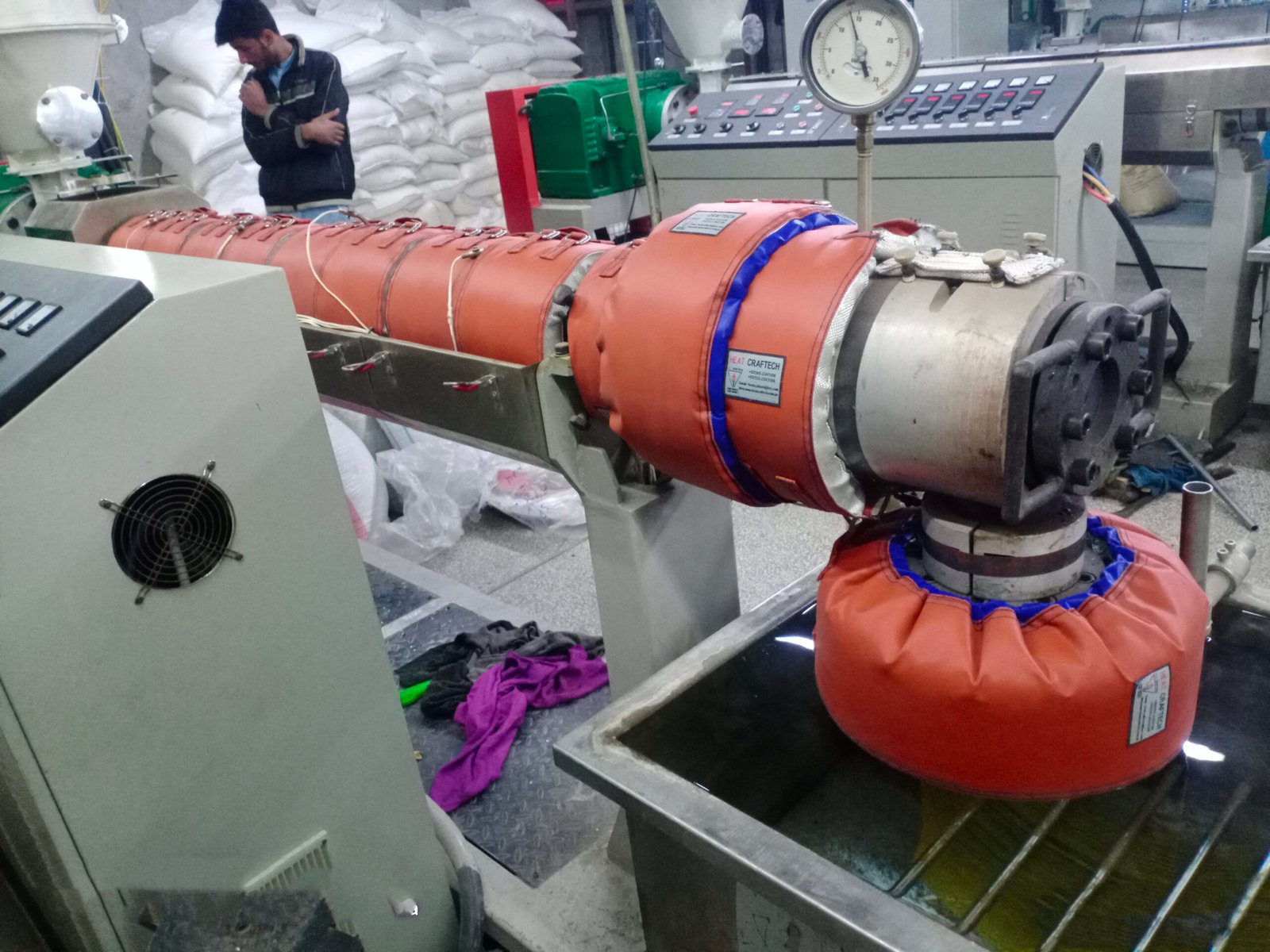

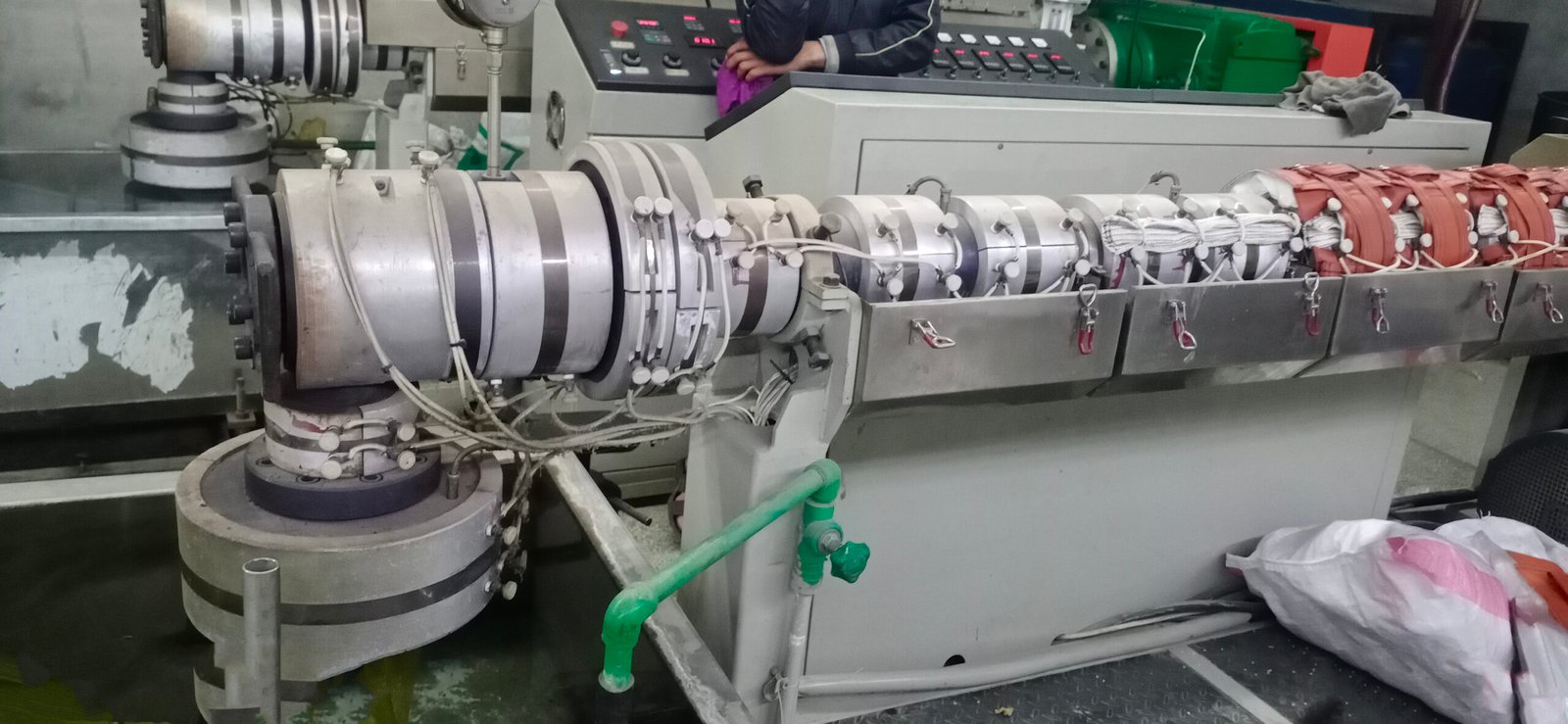

While Heat Craftech doesn’t directly manufacture mono filament, our expertise in heat management can be valuable for companies involved in its production.

- Temperature Control Systems: Precise control over the extrusion process is critical for mono filament production. We can provide solutions for maintaining consistent melt temperatures and ensuring uniform filament diameter.

- Heat Insulation Jackets: Custom jackets for extruders and other equipment can minimize heat loss and improve process efficiency.

Conclusion:

Mono filament, though simple in concept, offers a vast array of functionalities in our everyday lives. At Heat Craftech, we’re committed to understanding the various aspects of the plastics industry, and how our heat management solutions can contribute to efficient and optimized production processes.

Reviews

There are no reviews yet.