Description

we understand the intricacies of injection molding and the critical role that temperature control plays in this process. Inefficient heat management can lead to a variety of issues, including:

- Surface Defects: Uneven cooling can cause warping, sink marks, and surface imperfections on molded parts.

- Dimensional Inaccuracy: Inconsistent temperatures can lead to shrinkage or expansion of the molded plastic, affecting part dimensions.

- Internal Stresses: Rapid cooling can trap internal stresses within the part, potentially causing cracking or warping later.

- Reduced Production Efficiency: Molding defects and the need for part rejections can slow down production.

We offers a comprehensive approach to optimizing injection molding through strategic heat management:

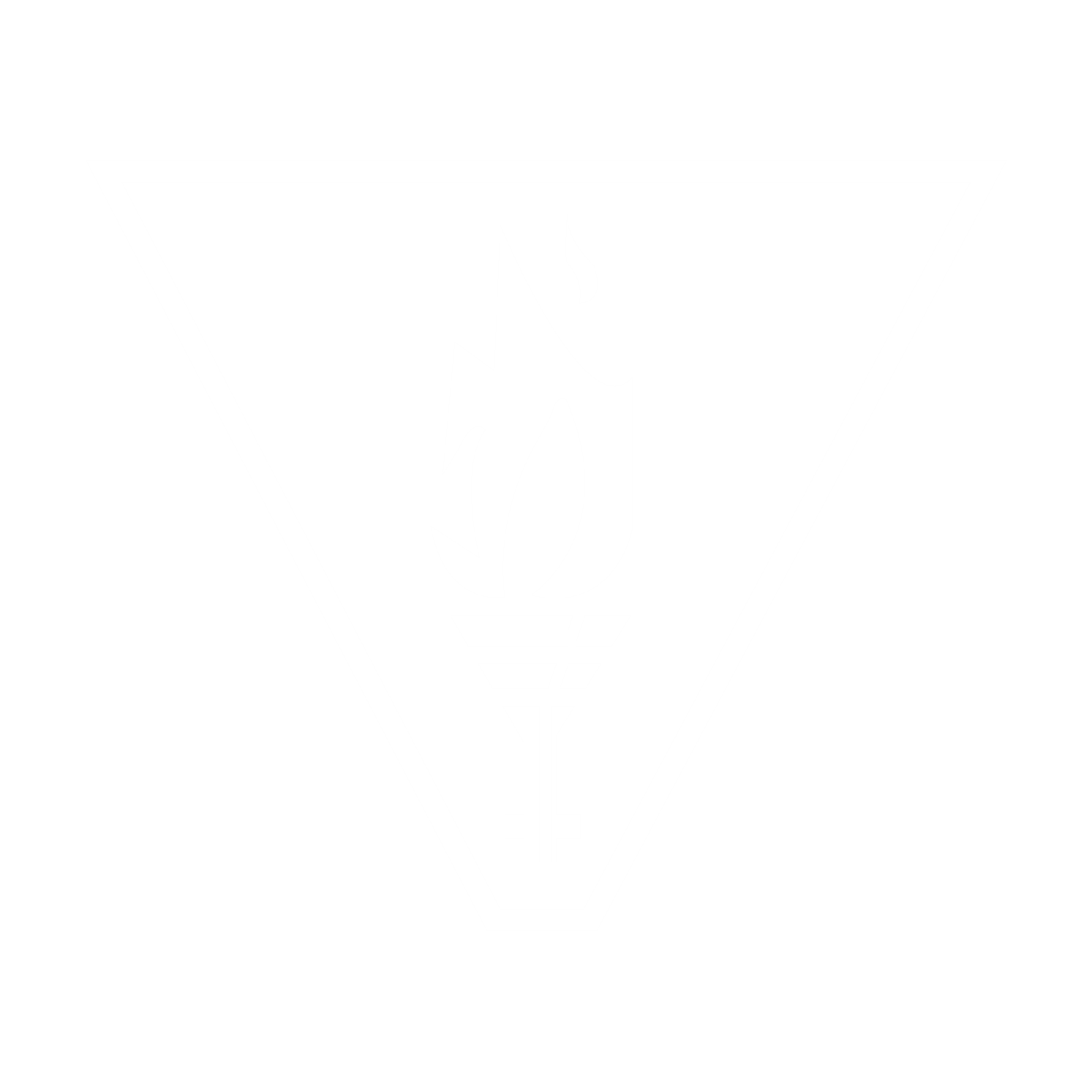

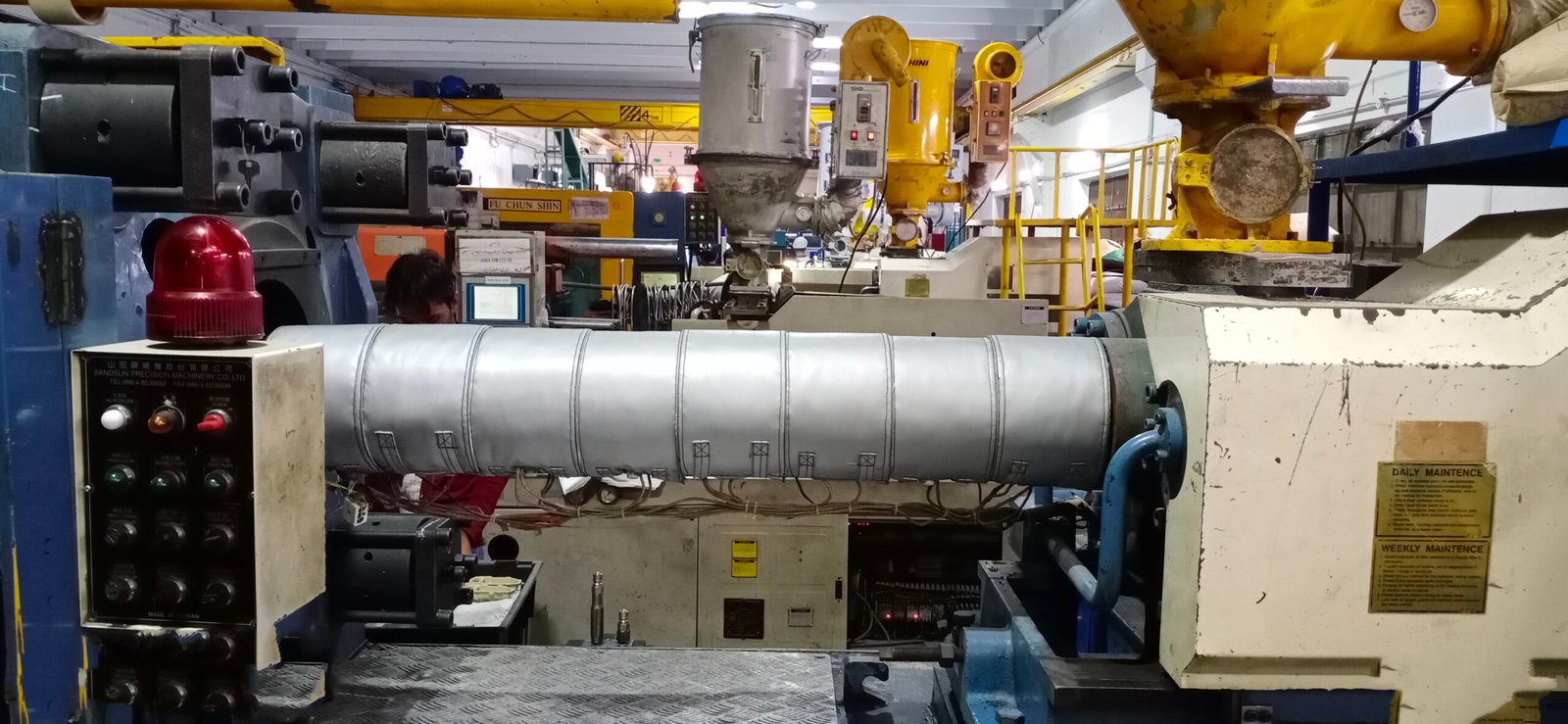

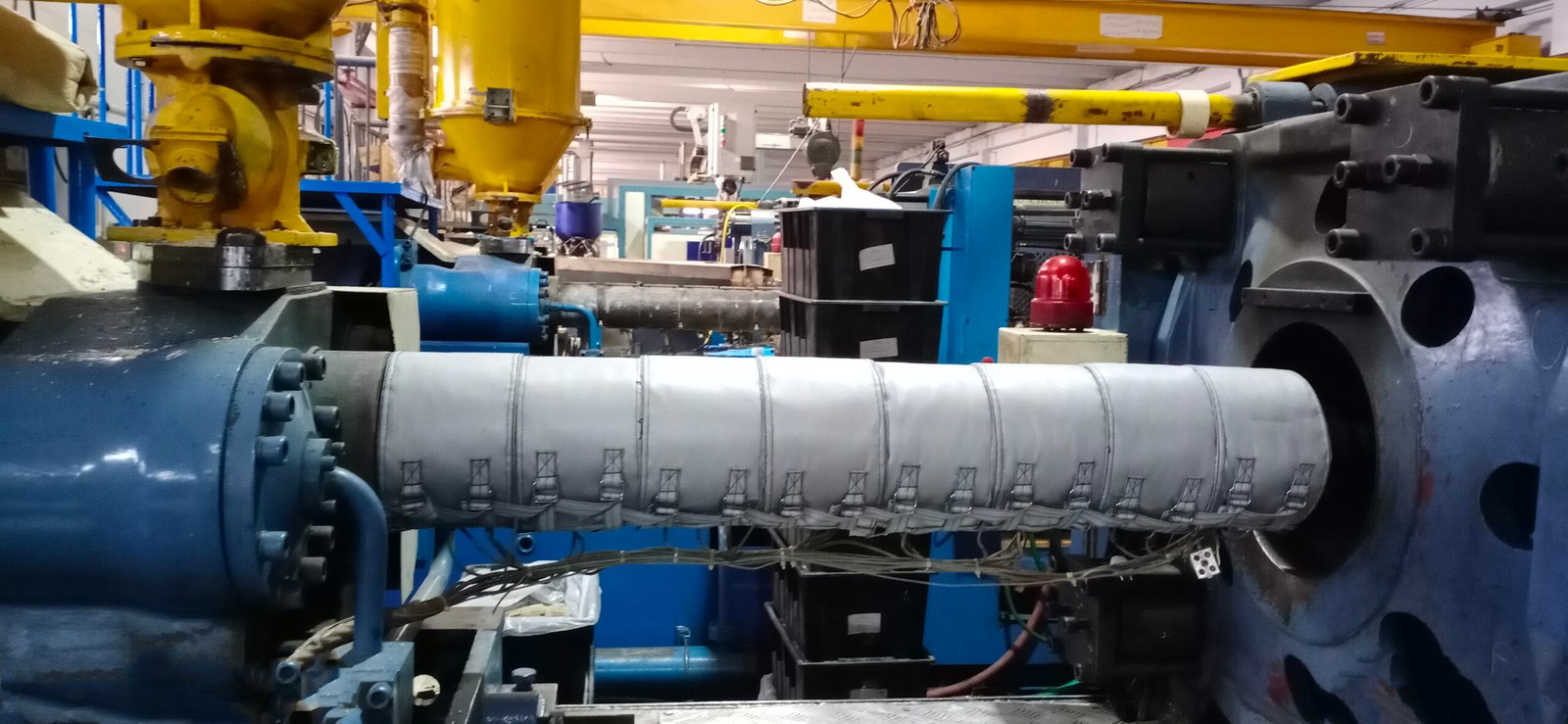

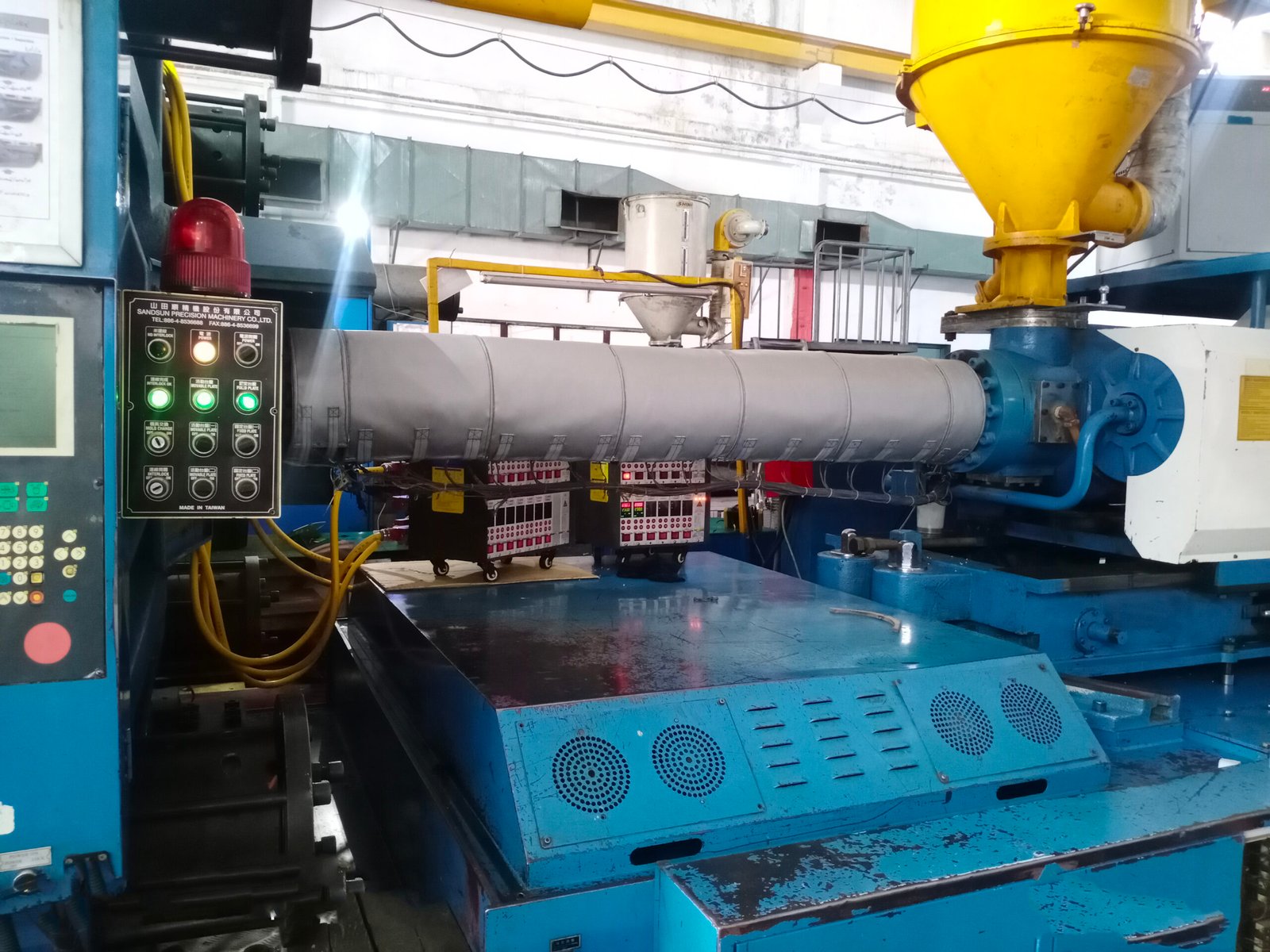

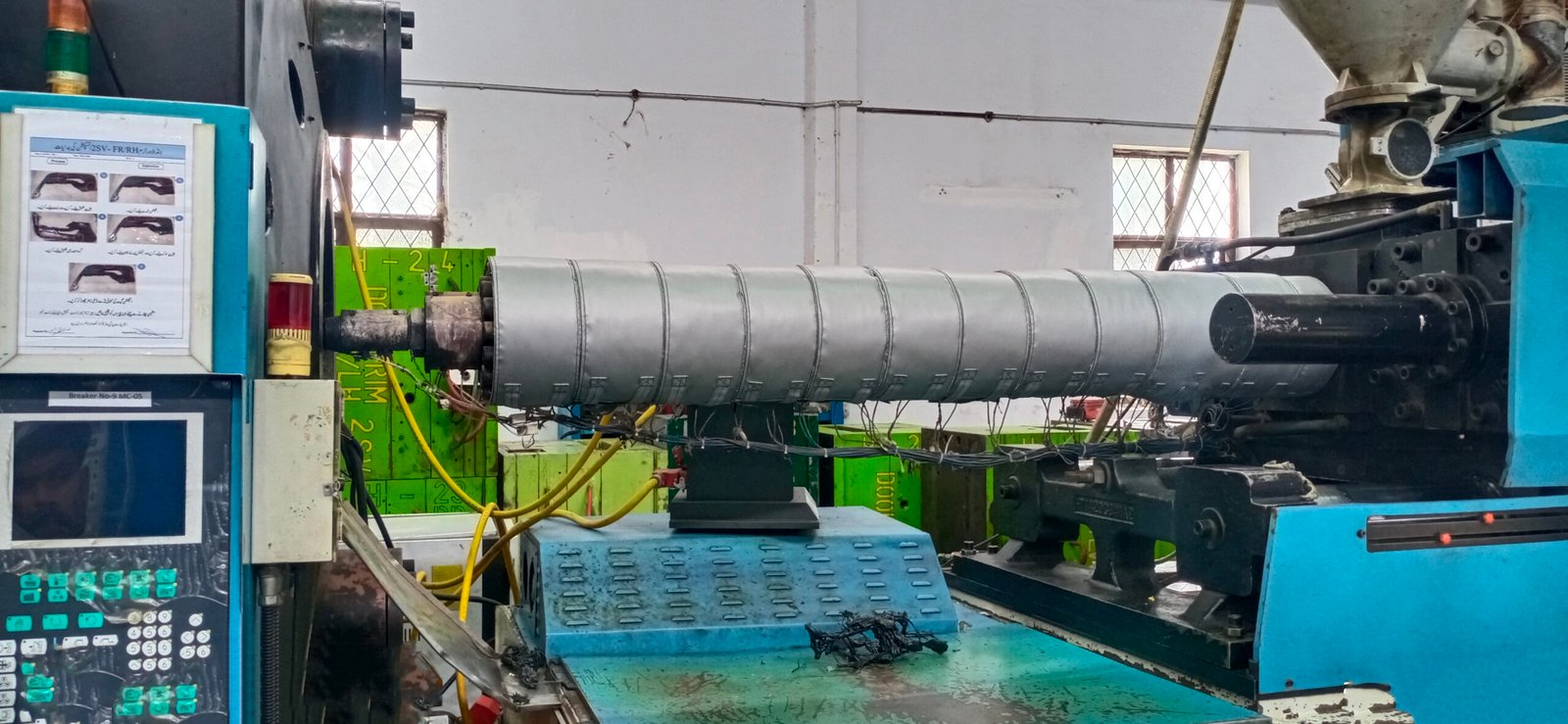

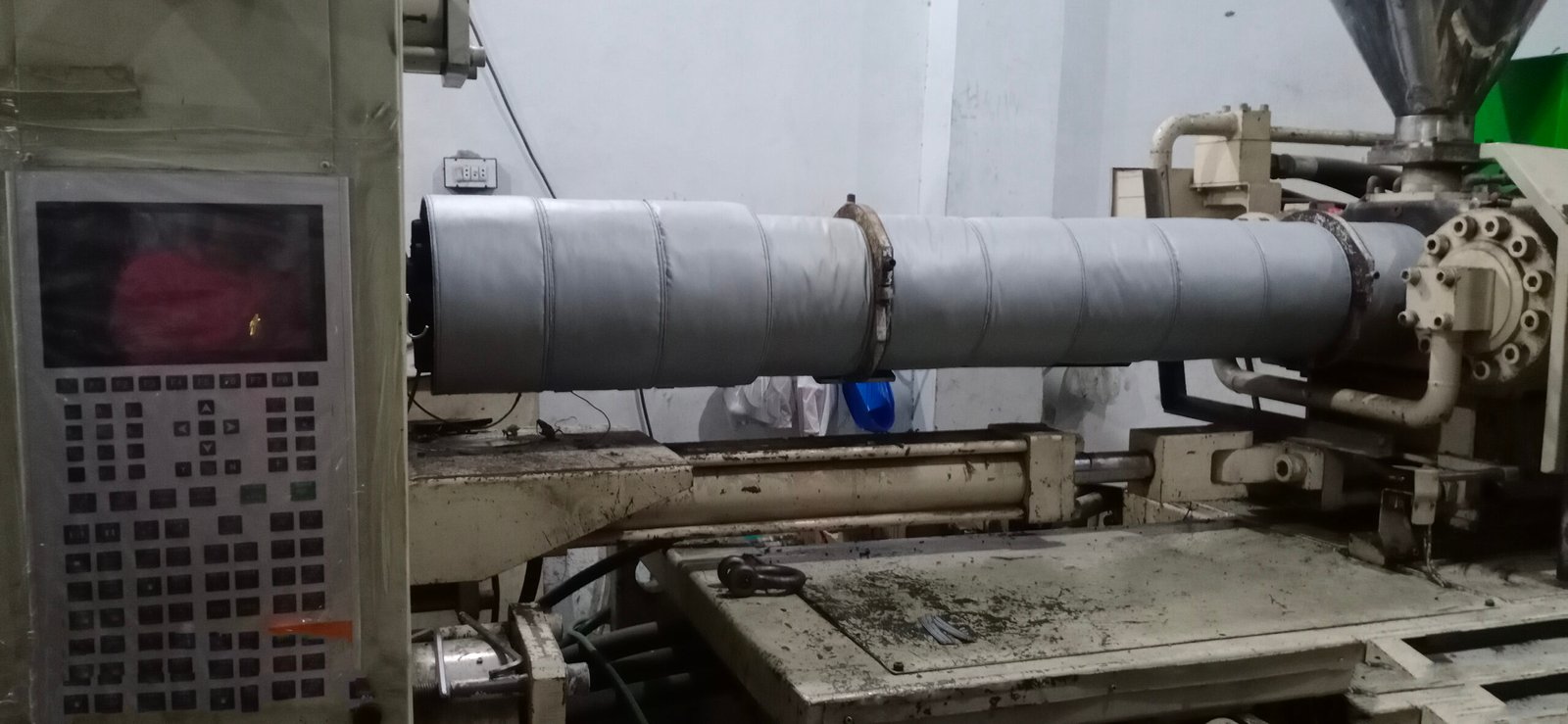

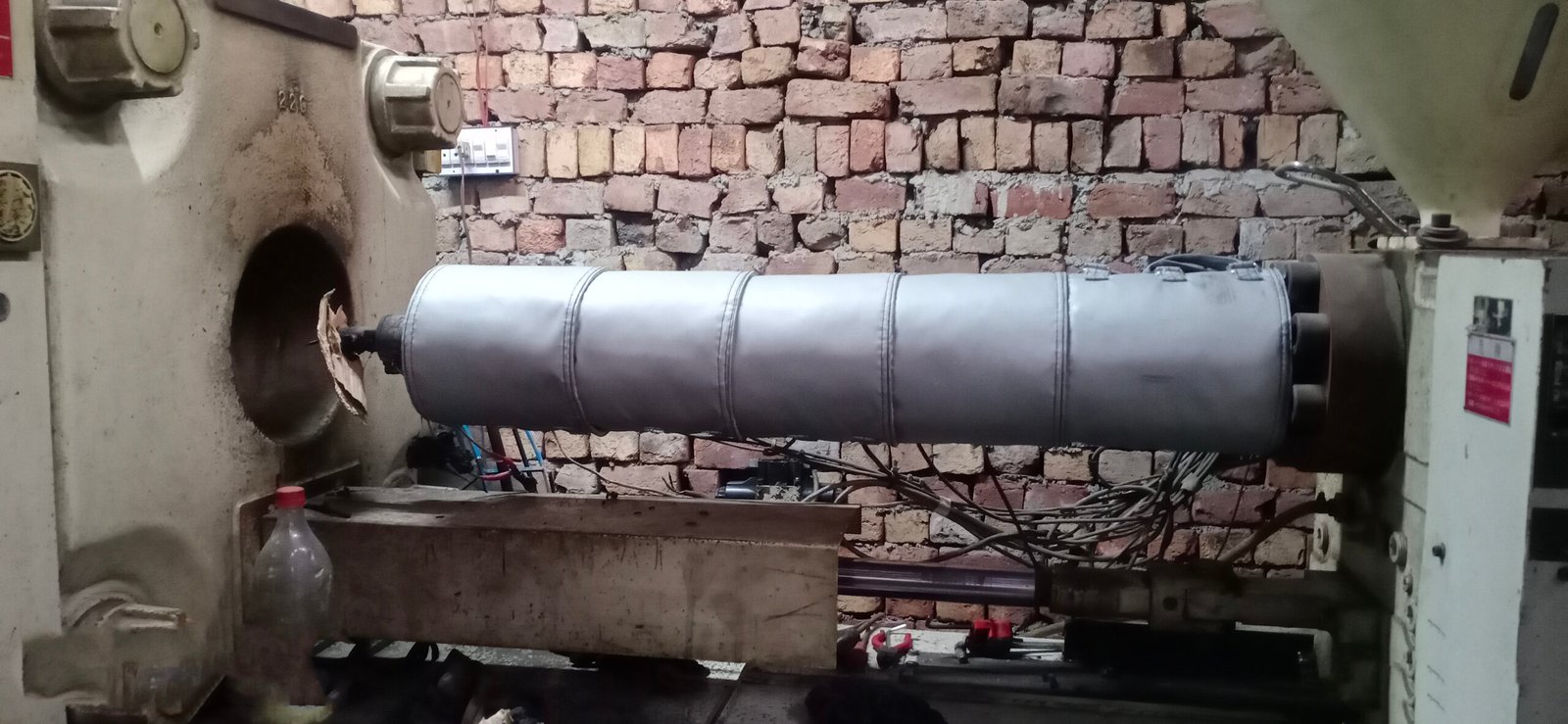

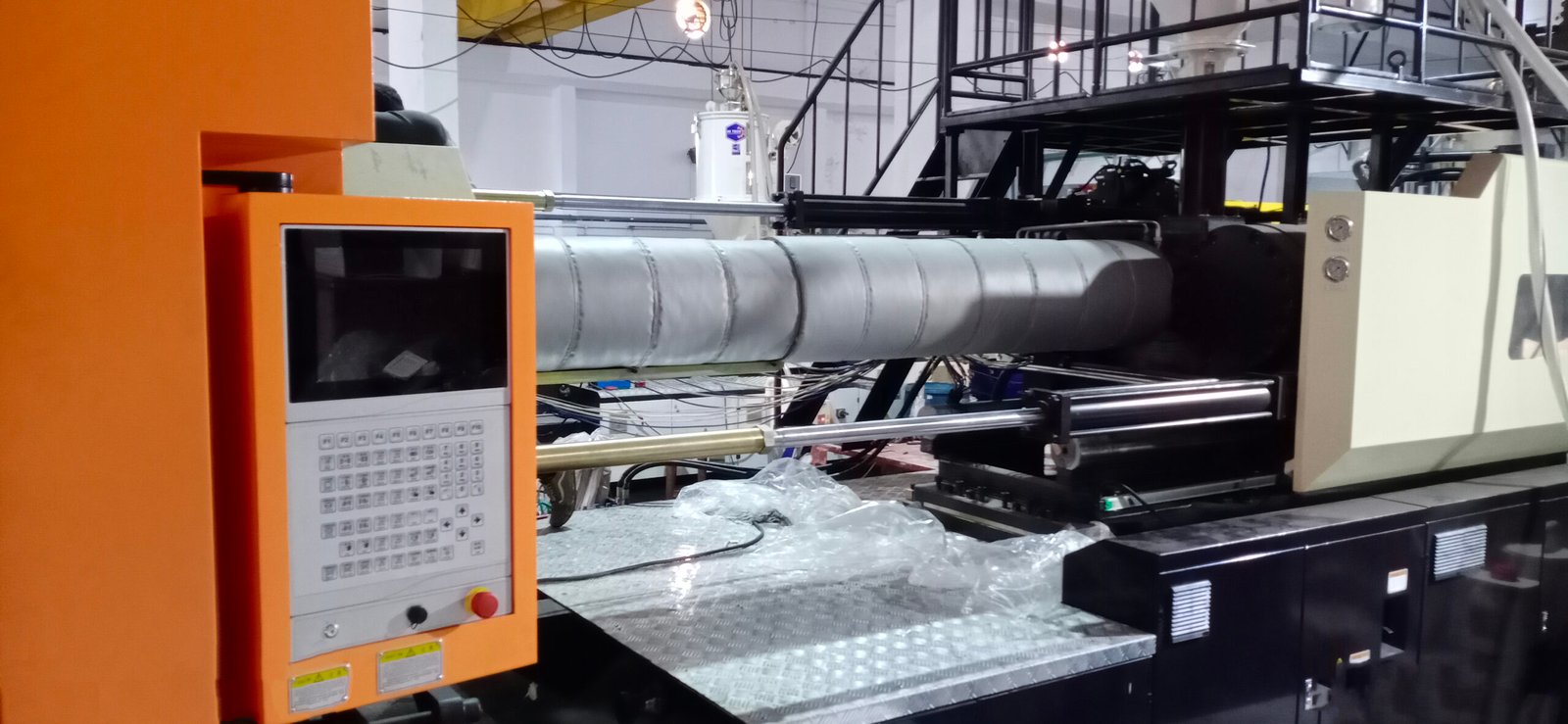

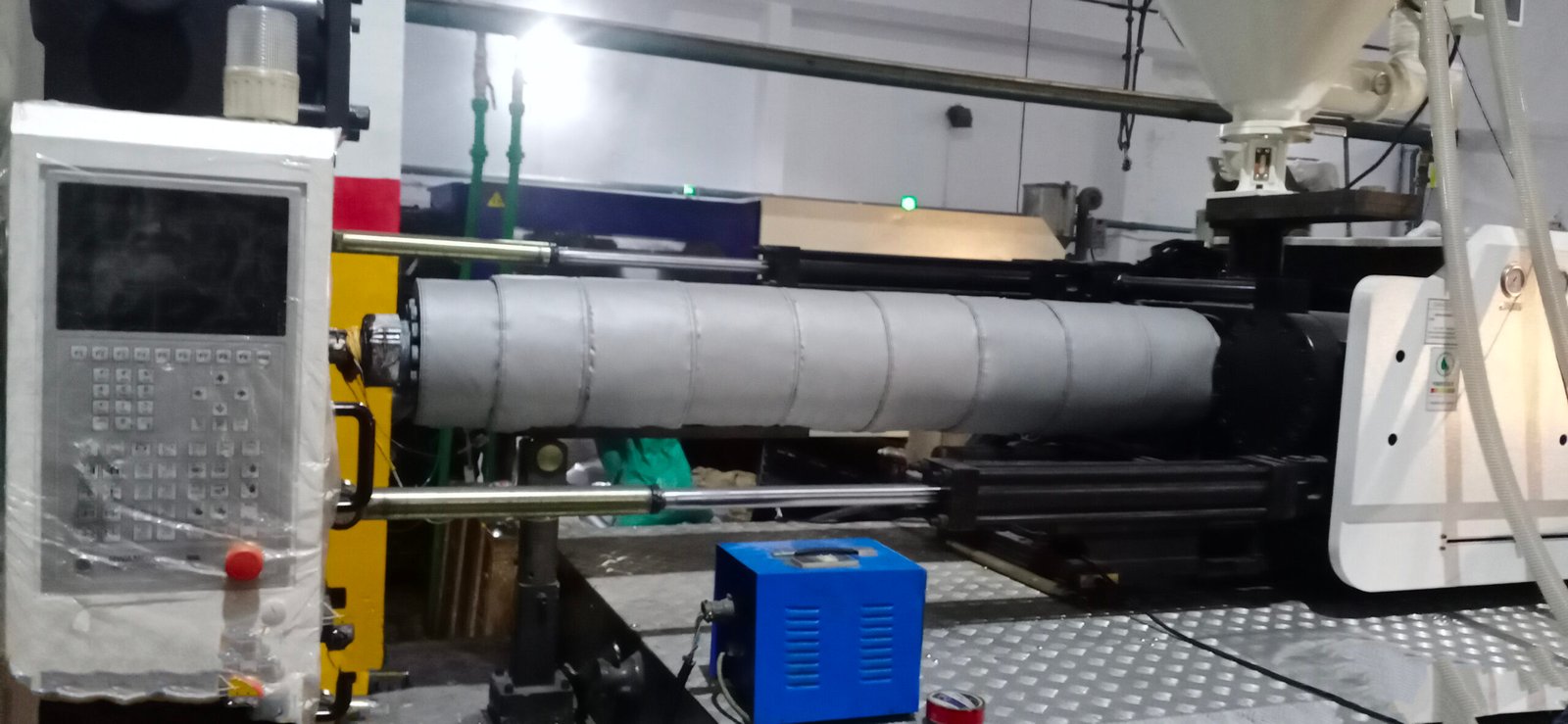

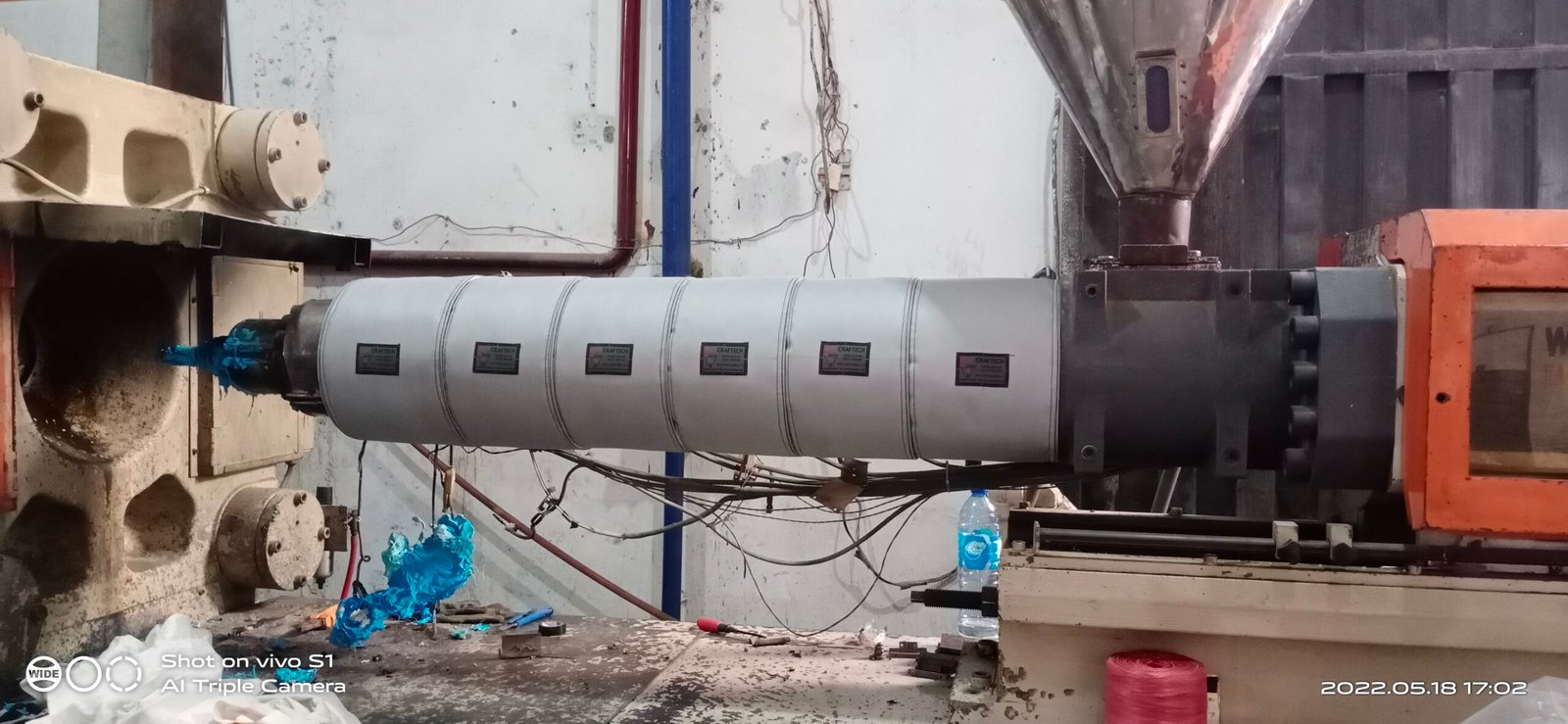

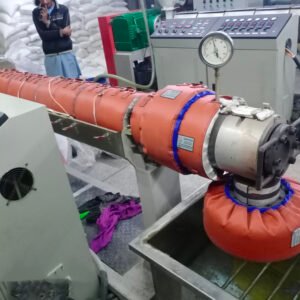

- Heat Insulation Jackets: Our custom-designed heat insulation jackets for injection molding machines provide superior thermal insulation for:

- Hopper and feed throat areas to prevent premature material cooling.

- Nozzles and sprue bushings to maintain consistent melt temperature.

- Platens to minimize heat loss and improve cycle times.

- Mold Temperature Controllers: We offer high-precision mold temperature controllers that ensure accurate and consistent heating and cooling of the mold throughout the injection molding cycle. This leads to:

- Improved part quality with fewer defects.

- Enhanced dimensional accuracy of molded parts.

- Reduced internal stresses for stronger and more durable products.

- Faster cycle times due to efficient mold temperature control.

Benefits for Injection Molders:

- Improved Product Quality: Achieve superior surface finish, dimensional accuracy, and overall part quality.

- Enhanced Efficiency: Reduce cycle times, minimize scrap rates, and optimize production output.

- Reduced Energy Consumption: Well-insulated machines and efficient temperature control lead to lower energy use.

- Cost Savings: Minimize material waste, production delays, and the need for part rejections.

Reviews

There are no reviews yet.