Description

Optimizing Production with Blow Molding Expertise

At Heat Craftech, we understand the versatility and efficiency of blow molding for creating a wide range of hollow plastic products. Whether you’re producing bottles, containers, industrial parts, or other applications, we can help you optimize your blow molding process.

What is Blow Molding?

Blow molding is a cost-effective and high-volume manufacturing process for creating hollow plastic shapes. Here’s a simplified breakdown:

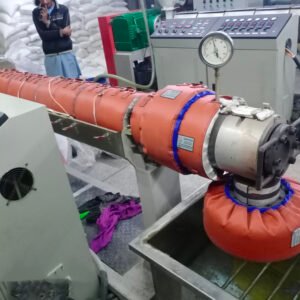

- Extrusion: Plastic resin pellets are melted and extruded into a hollow tube called a parison.

- Mold Clamping: The parison is captured between the halves of a closed mold.

- Inflation: Compressed air is blown into the parison, inflating it and conforming it to the shape of the mold cavity.

- Cooling and Ejection: Once cooled and solidified, the mold opens, and the finished hollow plastic product is ejected.

Benefits of Blow Molding:

- Cost-Effective: This process is ideal for mass production of hollow plastic parts due to its high speed and minimal material waste.

- Design Versatility: Blow molding can create a wide variety of shapes and sizes, from simple bottles to complex industrial parts.

- Lightweight and Durable: Blow-molded products are lightweight yet offer good strength and impact resistance.

Heat Craftech’s Role in Blow Molding Success:

We offer a range of solutions to enhance your blow molding operation:

- Heat Insulation Jackets: Our custom-designed jackets insulate key components like extruders and die heads, maintaining consistent melt temperatures and improving product quality.

- Temperature Control Systems: We provide precise temperature control solutions for the mold itself, ensuring uniform cooling and optimal cycle times.

- Technical Expertise: Our team of specialists can assist you with process optimization, troubleshooting, and selecting the most suitable blow molding equipment for your needs.

By partnering with Heat Craftech, you can achieve:

- Enhanced Product Quality: Consistent temperature control and reduced heat loss lead to superior product quality with minimal defects.

- Improved Efficiency: Optimized cycle times and minimized energy consumption contribute to a more efficient production process.

- Reduced Downtime: Proper equipment maintenance and troubleshooting expertise help prevent production delays.

Reviews

There are no reviews yet.